|

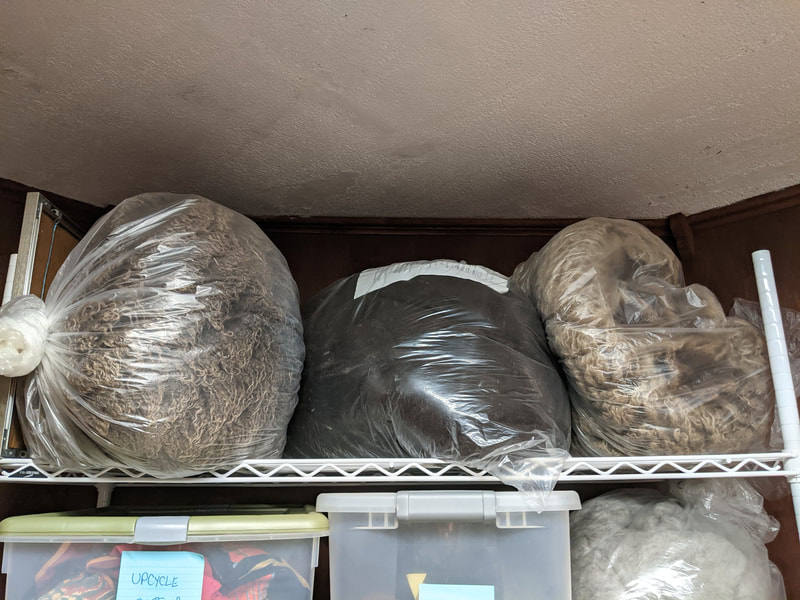

I had hoped that by now I’d be in a groove such that I could get some sewing and felting done each week. But for the moment I’m back working 6 long days/week because of staffing shortages, and on my one day off, I both rest and do all the household work that didn’t get done during the week. Somehow, I must find my way through to snatch both time and focus for the fiber work. It might help if I could narrow down that focus. First it’s clothing repairs, then overdyed denim that might be made into bags, or aprons, or jackets, or….. I miss the felt most, perhaps because it is the most amorphous, the most elemental, just fiber, a blank slate, more potential: possibly 2D wraps or wall hangings, possibly 3D masks or sculpture. It might help if I could narrow down that focus. Well, let’s get to the wool. The time of year dictates what I'm doing next. I have many bags of wool that need to be cleaned and combed before they can be worked into felt. Mostly Shetland and alpaca, white, moorit and deep rich browns and blacks. While the weather is still warm and sunny, I’m going to clean and dry them, and become reacquainted with these fleeces.

3 Comments

The mail is always heaviest on Mondays. Today, I steel myself for the long delivery day ahead by waking a bit earlier. I do a brief scroll on Instagram, and find a beautiful pic of a patch of lichen, a swirl of green and brown craters. I would love to reproduce this in felt, and file away that thought to ponder later. It’s raining hard when I wake. It rained two weeks ago, before Hurricane Elsa arrived, there were torrents of rain accompanying Hurricane Elsa as she passed through, and I get set for another rainy day. I don’t mind delivering in wet weather. I get wet, the mail gets wet. But being IN the rain actually feels quite peaceful: both daylight and air are softer, sound is muffled. I arrive at the post office, head to my carrel, and sort mail, setting up for the day. I’d hoped a caffeinated buzz could help me blast through setup, but this is the first workday that I’ve drunk coffee in more than a year, and I just feel hands-shakey jittery. I get through, and eventually I’m on the street, ready to deliver. The rain is much lighter, and eventually stops altogether, although it remains cloudy. I’m thankful for the respite from both the rain and the discomfort of carrying around a sopping-wet mailbag. While walking from house to house dropping off mail, it’s a balance between being sufficiently present so that I don’t miss an address or forget to drop a parcel, and being enough on autopilot so that I can think about sewing and feltmaking projects. I think about the Shetland fleeces I have yet to clean and would like to dye, and of the textures I’d like to incorporate in a series of wall hangings. A series! It’s so fun to think of making a series of objects, dreaming up and elaborating on the theme that connects each member of the group. But the mail is always heaviest on Mondays, and so the day is long and I am beat when I come home from a 10-plus hour day. I’d like to start planning out these wall hangings, make sketches and think about resists for the felt and what colors to use and preparing the wool, but perhaps not today, Monday, when the mail is heaviest.

I'm jumping around a bit here. I haven't finished the hat that I started in the previous blog post, some two weeks ago. Instead, I've been carding a lot of wool, anticipating future feltmaking efforts. It's a necessary task but I do wonder if I could have done this carding a lot earlier in the year, or if it's a procrastinatory tactic when I really should be making felt and refining some skills. Knowing when to appropriately prioritize tasks is time management skill I will probably need improving on forever. But anyway, carding wool.... I carded a LOT of the alpaca that I have because it's so easy to card...

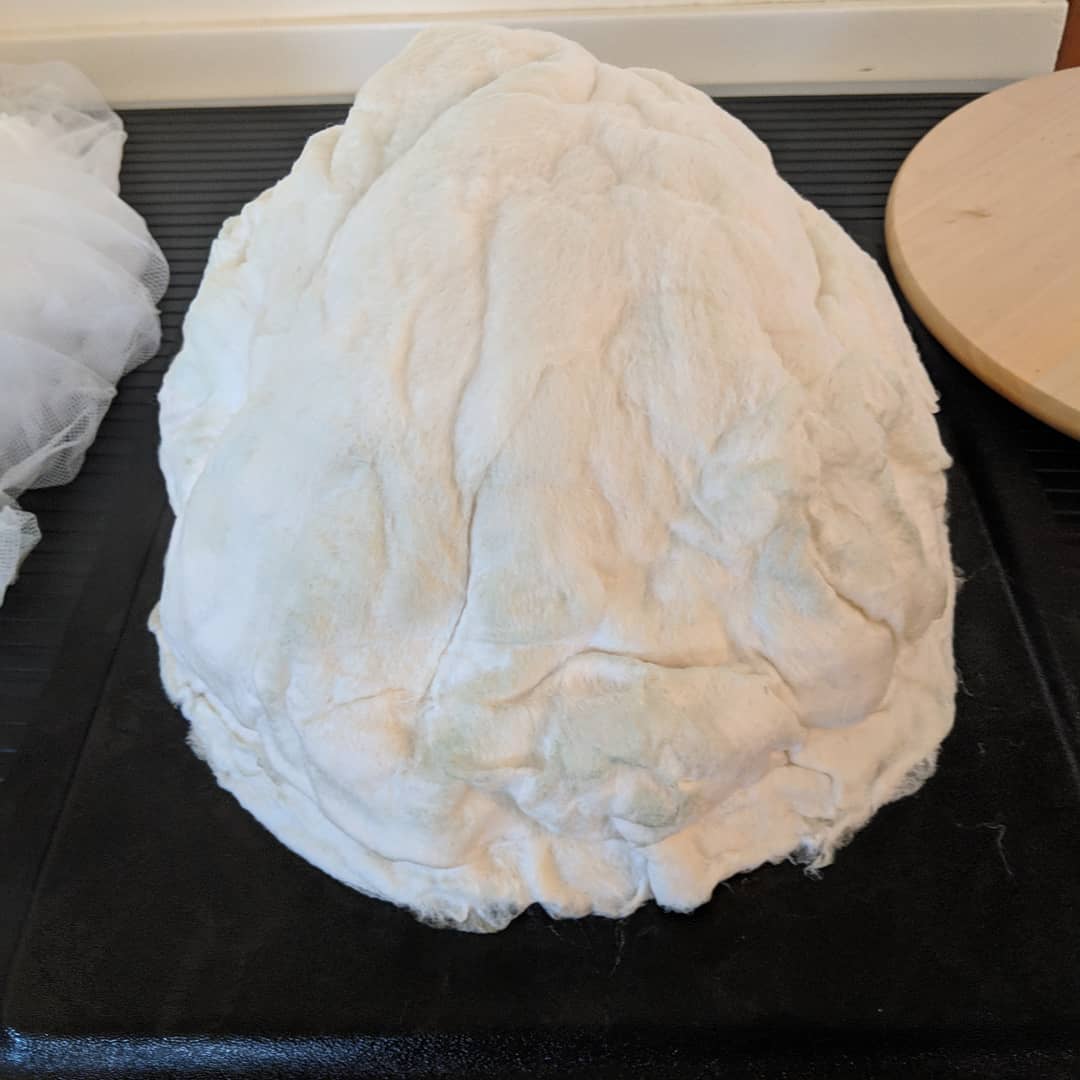

I'm starting to experiment with making hats. I got some hat forms and a shaping dome from Hat Shapers, which makes hat forms designed for feltmakers. The process is to first make the hood, and in its partly felted state, shrink down the hood onto the hat form. I've made hoods by molding fleece around a two-dimensional resist, but I thought using the shaping dome would more easily create a symmetric hood.

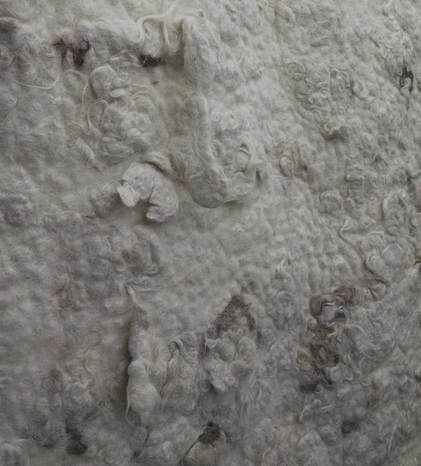

The first Icelandic wool that I ever worked with came from "trash fleece" given to me by a local farmer raising Icelandic sheep for meat. I'd read that Icelandic wool felts easily, and I was intrigued by a wool that was coarse yet felted so readily. Other breeds of coarse wools had been difficult to felt and I assumed that was true of all coarse breeds. Brought to Iceland by Vikings about 1100 years ago, Icelandic sheep have retained characteristics that have been bred out of modern sheep of the European continent. That includes having a "dual-fiber" coat, which has two layers. The fibers of the outer layer are called tog and are long, coarse and water-repellent; the fibers of the inner layer are called thel and are shorter, finer and provide the animal with insulation. In the era before industrialization, shepherds processed the wool by hand, differentiating the fibers into separate kinds of yarn. When mechanization was introduced to wool processing, the machines could not separate the two fibers and so they were combined into just one kind of yarn, called lopi. Lopi is also the name of an Icelandic wool company that sells Icelandic wool yarn. The fleece I got was knotty and full of vegetal matter, but not greasy, as Merino can be. Washing out the grease wasn't hard, but the knots made carding challenging.  I made a rug out of this fleece, shown above. Serendipitously, the knottiness of the dirty fleece created a lot of texture in the felt with random locks hanging off the body of the rug. The softer thel fibers, which seemed almost as fine as Merino, provided the cohesion, and the coarse tog fibers provided the texture. The felt came together quickly and easily. The felt doesn't shrink down as much as Merino would, but it is cohesive. I also learned that throwing the felt to shock and shrink it, which is a technique many felt makers use, can eject the coarse tog fibers from the piece, so it might be better to handle Icelandic felt with care. Maybe with all things, no? A while back, I was playing with the themes for this website and accidentally blew away all the blog posts that had been here. That was a bitter lesson learned about the pros and cons of the site builder that I use, but no matter. This is a chance for a do-over, and do we not all love a do-over? A do-nut to accompany this do-over would have do-nated to the excitement of a do-again, but perhaps that is just much a-do about nothing.

|

AuthorFeltmaking, dyeing, sewing. A woman and the fabric of her life. Archives

September 2021

Categories

|